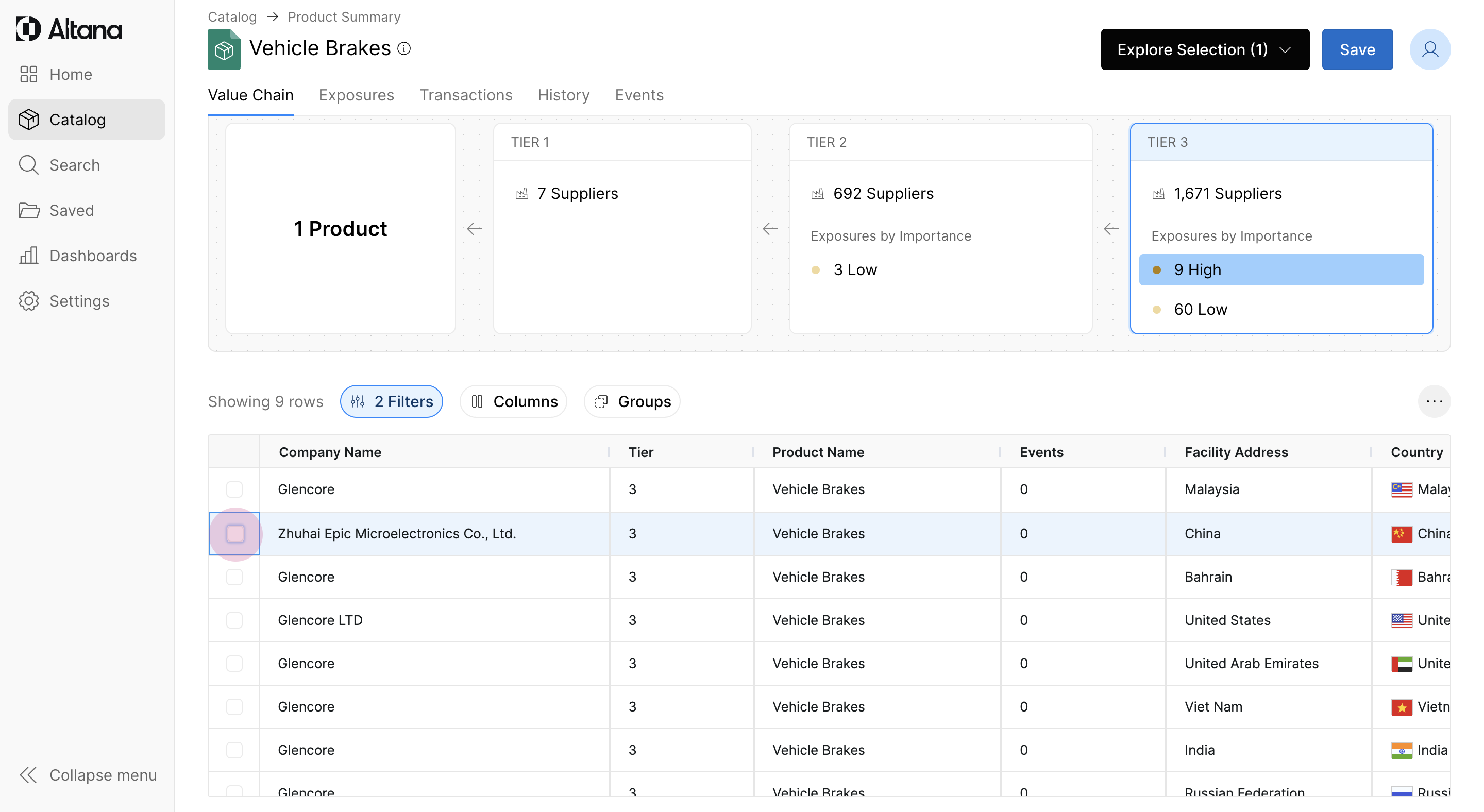

Evaluating Risk in Automotive Supply Chains

This guide provides a detailed walkthrough on how to assess risk in an automotive supply chain, focusing on a product related to vehicle brakes.

Step 1: Identify the product for evaluation. In this case, it's vehicle brakes.

Step 2: Investigate the exposures within the second tier of the supply chain. Here, an exposure related to Toyota Tsusho is identified.

Step 3: Analyze the risk exposure. In this instance, it's an indirect connection via the UFLPA geofence. The risk chain is exposed by two degrees of separation.

Step 4: Review the risk and mark it as a lower priority as it appears to be a retail sales and service operation as opposed to a manufacturing facility.

Evaluating Higher Priority Risk

Step 1: Identify a higher priority risk, this time upstream within the third tier. The supplier in this case is Zhuhai Epic Microelectronics.

Step 2: Examine the risk. It's found that Zhuhai Epic Microelectronics directly owns a facility located within Xinjiang province.

Step 3: Determine what the risky facility is shipping. Here, it's shipping goods related to aluminum, a priority commodity for enforcement for UFLPA.

Step 4: Translate the goods description if necessary. In this case, the description is in Spanish and translates to "heat sink" in English.

Step 5: Determine if the described good could potentially be a component for the product under evaluation. In this scenario, the heat sink could be a component for vehicle brakes.

Step 6: Mark the described good as a relevant material component.

Step 7: Mark the risk as escalated.